|

|

|

|

TITLE CENTER OF EXCELLENCE |

||

Project Name: Centre of Excellence 5-axis machining

Priority Axis: 2 Support R & D

Measure: 2.1 Promoting networks of excellent workplaces of research and development as pillars of regional development and promotion of subregional cooperation

Beneficiary: Slovak Technical University Bratislava

Project Name: Centre of Excellence 5-axis machining

ITMS Project code: 26220120013

Duration: From 01.05.2009 to 30.4.2010

Location: Faculty of Materials Science and Technology in Trnava

Address: J. Bottu 25, 917 01 Trnava

Objective of the project: The main objective of the project is to build a new Centre of Excellence supporting critical technology 5-axis machining.

Research will be carried out in the center of excellence:

- Stratagies of 5-axis machining,

- HSC CNC milling and routering complex shaped surfaces,

- CNC machining ultrasonic and laser machining of "difficult"

- the use of CA technology for CAD / CAM / CNC / CAQ.

CE5OM has the following departments:

1. WORKPLACE CNC HSC HIGH-TECHNOLOGY for 5-axis machining,

2. WORKPLACE CAD / CAM HIGH-TECHNOLOGY for 5-axis machining.

WORKPLACE CNC HSC HIGH-TECHNOLOGY FOR 5-axis CNC has the following machines:

- DMG HSC 105 linear

- DMG Ultrasonic20

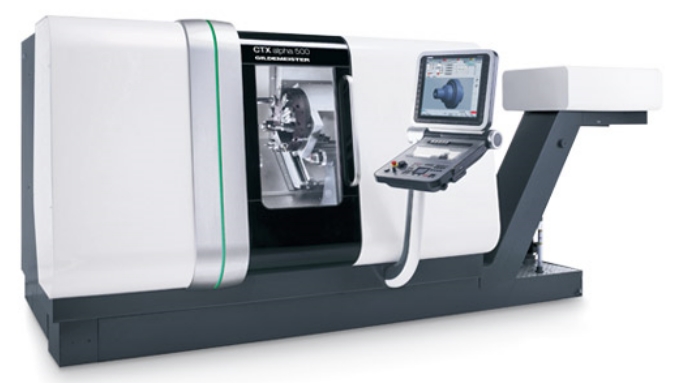

- DMG CTX 500 ALPHA

WORKPLACE CAD / CAM HIGH-TECHNOLOGY FOR 5-axis has the following software:

- PowerSHAPE CAD software

- PowerMILL CAM software

- CAD / CAM software ArtCAM

- CAD / CAQ software CopyCAD

DMG HSC 105

DMG Ultrasonic 20 Linear

DMG CTX ALPHA 500

CE5OM provides the following electronic services to the public, technical and professional experience created through the glove box:

1. The completeness and quality of the designed components in the 3D CAD model PowerSHAPE,

2. Generating of NC programs from 3D models for control systems Heidenhain iTNC 530, Heidenhain TURNPLU, Siemens 840D

3. Control and simulation of NC programs delivered

4. Control and creation of 3D surfaces from scanned data

To change large amounts of data such as 3D models, NC programs, scanned data, etc.. Use the "storage box" https: //sweb.mtf.stuba.sk/CE5OM.

Access rights

Name: ce5om

Password: ce5om

1. Delcam PLC

Small Heath Business Park, Birmingham, B10 0HJ. UK

The main purpose of the project is the research of CAM-CNC post-processors and to experimentally verify them on CNC HSC machines in the Centre of excellence of five-axis machining at the STU.

2. Technical University of Cluj - Napoca, Romania, Faculty of Machine Building

The main purpose of the research project is to develop theoretical concepts of CAD-CAM-CNC for special globoid cams manufacture, and to experimentally verify these concepts in the Centre of Excellence.

Scientific goals:

a) Research the influence of Five-Axis CAM strategies on achieving dimensional accuracy and roughness of CNC machined surfaces - the globoid cams.

b) The transfer of these research results into the development of study programmes at both universities.

3. Kecskemét College, Hungaria, Faculty of Mechanical Engineering and Automation

Scientific goals:

The main purpose of the research project is to develop theoretical concepts of monitoring of HSM of 5-axis machining and to experimentally verify these concepts in the Centre of Excellence.

The detailed goals:

a) Research of the strategies for High Speed Monitoring of High Speed Machining in 5-axis machining.

b) The transfer of these research results into the development of study programmes at both universities.

1. Technical University of Cluj - Napoca, Romania, Faculty of Machine Building

Goals of this exchange programe:

The main purpose of the exchange programme is the know-how exchange in the areas of:

-

- 5-axis machining and

- globoid cams manufacture.

- The exchange of students for the short-time stay.

Realizácia:

In the period: from 5th of April 2010 to the 3rd of December 2010 , i.e. for 245 days

Mr: Pestean Stelian Viorel

Citizenship: Romanian

Residential at: Streiului, Nr. 1. Bl. A 14. Sc. III. ap. 83, Cluj-Napoca, Romania

Position in the organization: PhD. student

2. Kecskemét College, Hungaria, Faculty of Mechanical Engineering and Automation

The main purpose of the exchange programme is the know-how exchange in the in the areas of:

- High Speed Machining for 5-axis milling and

- High Speed Monitoring of 5-axis milling process.

- The exchange of students for the short-time stay.

- The exchange of researchers and teachers for the short-time stay.

- Survey - Center of Excellence 5-axis machining - workers from practice

- Help for problems with accessing the site

- Survey - Center of Excellence 5-axis machining - Students in other courses such as Computer Aided

- Help for problems with accessing the site

prof. Dr. Ing. Jozef Peterka - Head- jozef.peterka@stuba.sk

doc. Ing. Peter Pokorný, PhD. - Deputy Head - peter.pokorny@stuba.sk

Ing. Ladislav Morovič, PhD. - Solutionist - ladislav.morovic@stuba.sk