Laboratories

Head of laboratory: GÖRÖG Augustín, doc. Ing. PhD.

Our metrology laboratory is where our students, researchers, and partners work to understand and practice metrology, which is the science of measurement. Undergraduate and graduate students use the laboratory during their studies and mainly during writing their bachelor or master theses. As well as manual metrology devices, the lab offers the following equipment, which can be used by students. The laboratory is also available to help students for their projects. Laboratory equipment is also used for the realisation of small projects for companies.

Machines and equipment:

- Coordinate Measuring Machine Zeiss Prismo Ultra,

- Surface Roughness and Contour measuring instrument Surfcom 5000,

- Roundness Measurement Instrument Rondcom 60A,

- Manual metrology devices and Measurement microscopy,

- Software Calypso, AccTee.

Partners: Carl Zeiss Slovakia, s. r. o., ZEISS Metrologické centrum Trnava

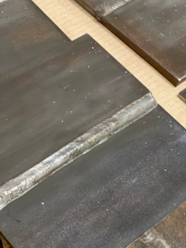

Head of laboratory: BÁRTA Jozef, doc. Ing. PhD. IWE IWI-C

The faculty has a modern welding laboratory that has been completely renovated. It is adapted for manual as well as automated welding. The faculty also has its own welding school, where it conducts basic welding courses according to STN 05 0705, exams according to STN EN ISO 9606-1 as well as welding operators according to STN EN ISO 14732. Available technologies are oxy-fuel welding, MAG/MIG, TIG, TOP TIG , CMT, plasma arc welding, laser beam welding, electron beam welding. In addition to education activities, we also focus on research and development activities, welding small series for companies and also analysis of welded joints in terms of mechanical testing and non-destructive testing.

Machines and equipment:

- Laser workplace for laser cutting and welding with a Trumpf Trudisk 4002 source

- Electron beam technological complex with cannon output power of 30 kW

- Experimental workplace of arc and plasma technologies

- MIG/MAG welding source

- Welding source TOPTIG

- CMT welding source

- TIG welding source

- Welding source for plasma/micro plasma welding - NAC Memrecam NX-3 high-speed camera

- Device for independent measurement of welding parameters

Partners:

First Welding Company, inc.

Revol TT Consulting, Ltd.

PGS Automation, Ltd.

TRUMPF Slovakia, Ltd.

Fronius Slovakia, Ltd.

Binzel Alexander - zváracia technika, Ltd.

Classrooms

Head of Classroom: VÁCLAV Štefan, doc. Ing. PhD.

The classroom provides our students, researchers and partners with the

necessary background for a quality learning process. Bachelor and engineering students use the classroom for the teaching process. The classroom provides a place for standard teaching and also a place for professional course in Technology and construction in practice, which is realised annually with Schaeffler Skalica. The professional course occurs at MTF STU in Trnava and Schaeffler Skalica. In addition to acquiring professional knowledge, each student gets a certificate of professional course completion. In the Schaeffler classroom, there are also demonstrations of the Schaeffler Skalica production program, which students use during their studies.

Partner: Schaeffler Skalica, spol. s r.o.

Head of laboratory: KURUC Marcel, doc. Ing. PhD.

Computer Classroom I is equipped with powerful computer stations with CAD/CAM/CAQ/CAA software. Computer aided design is carried out in Autodesk PowerShape and Fusion 360. Computer-aided production is executed in Autodesk PowerMill and Featurecam software. The software is determined to generate the trajectories of 3-axes and 5-axis milling as well as multi-axis turning. The advantage is represented by the possibility to generate the trajectories for industrial robots and devices for additive production. The laboratory also has Calypso software at its disposal; this software is used in programming the trajectories of characteristics measurement on coordinate measuring machines. Workstations no. 24.

Students will gain practical experience with many industrially used software: they will learn to model complex parts and assemblies; create drawings and NC programs; use generative design, topology optimization, parametric modelling, reverse engineering; create various stress and thermal simulations; create paths for multi-axis machining and measurement of shapely complex parts, as well as design entire production and assembly workplaces.

Equipment and softwares:

- Autodesk PowerShape, Fusion 360, PowerMill, FeatureCam, Inventor

- Tecnomatix, SinuTrain, Heidenhain,

- Deform 3D, GOM Inspect, SolidWorks,

- Calypso, Zeiss Reverse Engineering,

- MSC ONE software.

Students will gain practical experience with many industrially used software: they will learn to model complex parts and assemblies; create drawings and NC programs; use generative design, topology optimization, parametric modelling, reverse engineering; create various stress and thermal simulations; create paths for multi-axis machining and measurement of shapely complex parts, as well as design entire production and assembly workplaces.